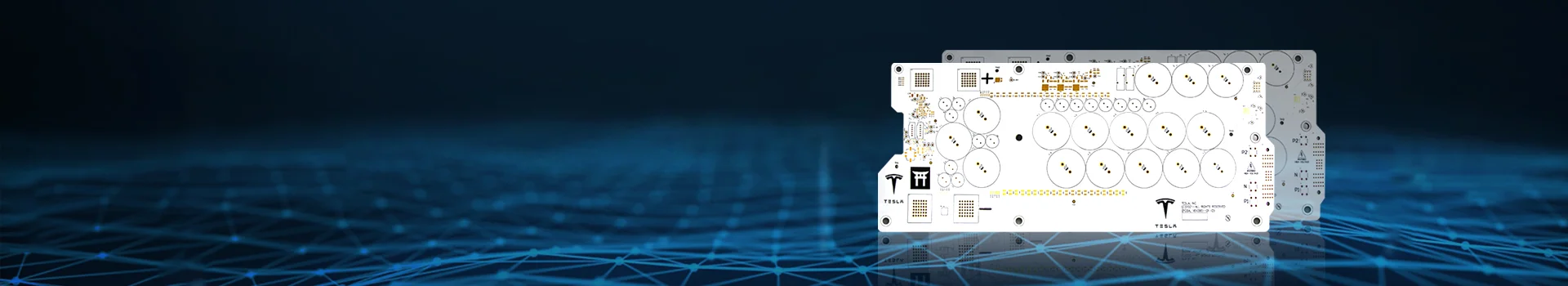

Lead free welding of multilayer board

Circuit board manufacturer explains lead-free welding of multilayer board

Circuit board manufacturer explains lead-free welding of multilayer board

Analysis of phosphorus content in lead-free solders for circuit boards

The circuit board is often accidentally damaged during assembly or testing. Even after the PCBA is assembled, it will still be accidentally impacted by external forces. Sometimes even the copper pad on the PCB board is lifted by force and floats away.

Multilayer and double-layer panels are similar in design for easier wiring. First of all, the layered structure should be divided, with the substrate as the center and symmetrically distributed on both sides, and the adjacent signal layers should be separ

There are several considerations in the assembly and production of PCBA circuit boards. After the soldering and conformal coating steps of the PCB assembly process are completed, our quality assurance team will conduct a final inspection - testing the PCB

What design documents should be included in SMT PCBA assembly

Design Scheme of Simple Process Side Tooling for PCBA Board Removal

The circuit board manufacturer explains how to prevent false soldering and false soldering during PCBA processing? What are the methods

Reasons and Solutions of PCBA Circuit Board Processing Throwing

What are the undesirable phenomena of PCBA processing and welding? Cause analysis

What is the reason for PCBA processing faulty soldering? What's the solution

This article mainly introduces the common defects and solutions in FPC manufacturing process. The characteristics of PCB double-sided board and the reasons for complex process

電話熱線

13410863085Q Q

微信