As the core carrier of electronIC products linking components, only highly reliable and high-quality PCB can meet the development needs of customers.

Under the background of "5G+", "Industry 4.0" and "Intelligent Manufacturing", the concept of PCB, as a basic material, has become one of the most widely concerned and sought after plates. No matter how the MARKet develops, PCB is the most frequently used demand in production, and also an indispensable part of the electronic industry.

With the continuous improvement of living standard and consumption level, the end consumers pay more attention to the user experience and high-tech content of electronic products. The upgrading of electronic products is accelerated, and the continuous development and rapid transformation of new technologies, new materials and new designs have provided a broad space for the development of PCB industry and ushered in new growth points.

Always in the key link "off the chain"?

At present, with the rapid development of PCB industry, the market competition is no longer independent innovation ability, but efficiency. Can we keep up with the market quickly with high efficiency and low cost. In this rapidly evolving and challenging environment, we still face some problems:

1. There are many types of PCB brands, so I don't know how to choose them;

2. The tradition is single, unable to meet multiple design requirements;

3. High cost, low efficiency and slow delivery;

4. Poor process and poor solderability;

5. Ordinary PCB board has poor stability, complexity and low compatibility.

How to break this barrier? How to avoid minefields among many manufacturers? When customers' purchasing habits are changing and the industry competition is becoming increasingly fierce, how should manufacturers meet customers' new order needs.

What can the Creation Workshop bring?

In the case of unstable market fluctuations, PCB industry is an industry that attaches great importance to delivery date and quality. From the current situation, few PCB manufacturers can guarantee both delivery date and product quality. Instead of choosing low-end factories, it is better to choose high-end boards and high reliability PCB boards to make customers more confident. As a leading electronIC design and manufacturing service integrator in China, Creator Factory focuses on high-end multilayer PCB, provides one-stop services from design, manufacturing, creativity to product hardware innovation, and constantly sharpens its ultimate process capability. To create high-quality boards with high efficiency, high quality and leading technology, and provide customers with the best solutions for product performance, cost and manufacturing cycle. With the highest quality service, Creator Works can help users quickly win benefits in the market and gain competitive advantages.

(1) The platform places orders quickly online, with transparent prices, and bid farewell to tedious consulting, greatly shortening the quotation time;

(2) Fast feedback, online order submission or product demand, specially assigned person to accept;

(3) Mature and rich PCB manufacturing experience to ensure that the delivery date and quality can be effectively controlLED;

(4) 100% quality assurance, full compensation for defective products.

Outstanding strength to create efficient collaboration

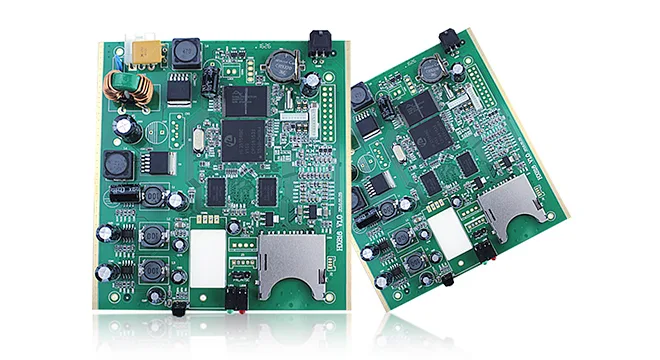

Conventional PCB is the foundation and guarantee. The Creator Workshop, guided by the needs of research oriented customers, insists on systematic design first, and provides customers with high-speed PCB design and value-added services. Only by effectively improving the reliability of PCB, can it help customers improve brand reputation and continuously enhance market competitiveness.

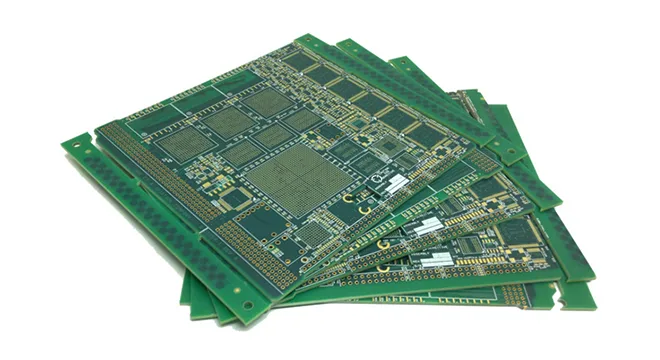

The Creator Workshop platform provides a series of high standard PCB products, such as multilayer PCB up to 64L, HDI PCB, rigid flexible PCB, heavy copper PCB, high-frequency PCB, high-speed PCB, high TG PCB, impedance control PCB. These products include a wide range of top-level laminates (such as Rogers, Panasonic, Shengyi, etc.). It has industry-leading PCB technology, such as maximum 64 layers, 12mm finished board thickness, 15oz heavy copper and minimum 2.5/2.5ml line width and spacing.

Speak with value to help the industry develop

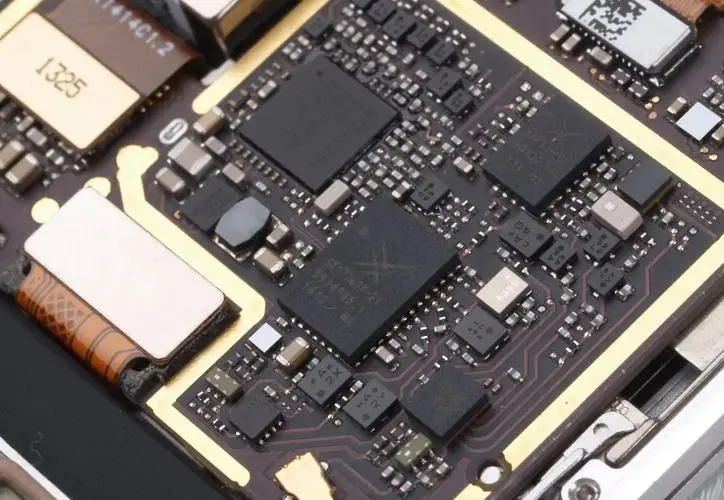

Take a communication industry as an example. The customer's technical difficulty lies in that the main chip XC7VX690T of the product has nearly 2000 pins and 9 DDR3s. There are more than 200 pairs of 5G differential signals and more than 400 pairs of 1G differential signals in the board. There are many kinds of power supply, dense space, and limited layers of plate thickness.

After the implementation of the project, combined with the factory process, reasonable layout planning, adjusting the network to make the signal connection smooth, SI SIMulation assistance, sorting out and summing up a variety of power supplies, and considering the heat dissipation design,

PCB design, PCB production and welding took less than 4 weeks to complete all the work.

Benefit from flexible and efficient products

Based on Internet plus collaborative manufacturing, the creation workshop platform realizes digital and information-based innovative services, covers the whole process system architecture of product launch, meets the full process information-based support from inquiry, launch and progress monitoring, and can view the production progress online at any time and anywhere to understand the latest situation of products.

At present, the product business is widely used in electric power, intelligent hardware, communication, medical treatment, automobile, industrial control, Internet of Things and many other fields. With the use of modern production innovation technology, it provides customers with fast and fast customized design services to help China's PCB industry develop at a high speed.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱