On Selective Wave Soldering in PCB Manufacturing

Up to now, many PCB boards are still in the process of wave soldering, and the wave furnace has been put into the museum! However, most of what is going now is the selective wave soldering (Selective Wave Soldering) process, rather than the early process of soaking the whole panel in the tin furnace

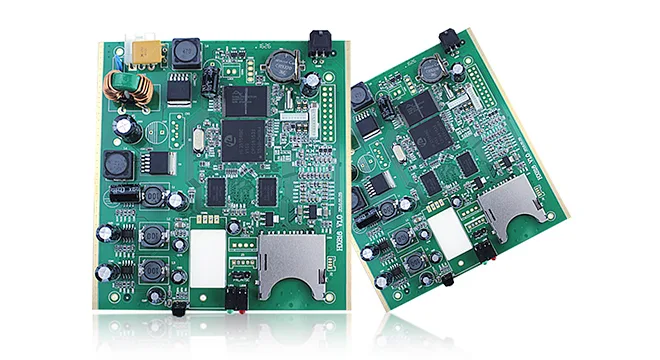

Wave soldering

The so-calLED selective wave soldering still uses the original tin furnace. The difference is that the circuit board needs to be placed in the tin furnace carrier/tray (carrier), and then the part that needs wave soldering is exposed and tinned. The other part is covered with a carrier to protect it, whICh is a bit like placing a life buoy in a swimming pool. The area covered by the lifebuoy will not be flooded. If the tin furnace is used for replacement, the area covered by the carrier will not be polluted by tin, and there will be no problem of remelting tin or parts falling.

However, not all circuit boards can use the selective wave soldering (selective wave soldering) process. If you want to use it, there are still some design limitations. The most important condition is that these parts selected for wave soldering must be compatible with other parts. Parts that do not need wave soldering have a certain distance, and this can be used to make solder furnace carrier.

Precautions for carrier and circuit design of selective wave soldering:

When the solder joint of a traditional solder piece is too close to the edge of the carrier, due to the shadow effect, the problem of insufficient solder joints is likely to occur.

Polychlorinated biphenyls

The carrier must cover the parts that do not need to be welded with the tin furnace.

It is recommended to maintain a wall thickness of at least 0.05 – 1.27mm at the edge of the carrier hole to prevent solder penetration into parts that do not need to be welded with a tin furnace.

For the parts to be welded with tin furnace, it is recommended to keep at least 0.1 – 157 away from the edge of carrier hole; (2.54mm) to reduce possible shadow effects.

The height of parts passing through the furnace surface shall be less than 0.15 – 3.8mm, otherwise the furnace bracket will not cover these high parts.

The data of the welding furnace carrier shall not react with the solder, and must be able to withstand repeated high-temperature cycling without deformation, not easy to absorb heat, and be as light as possible with SMAll thermal shrinkage. At present, there are more people. The materials used are aluminum alloy and also synthetic stone.

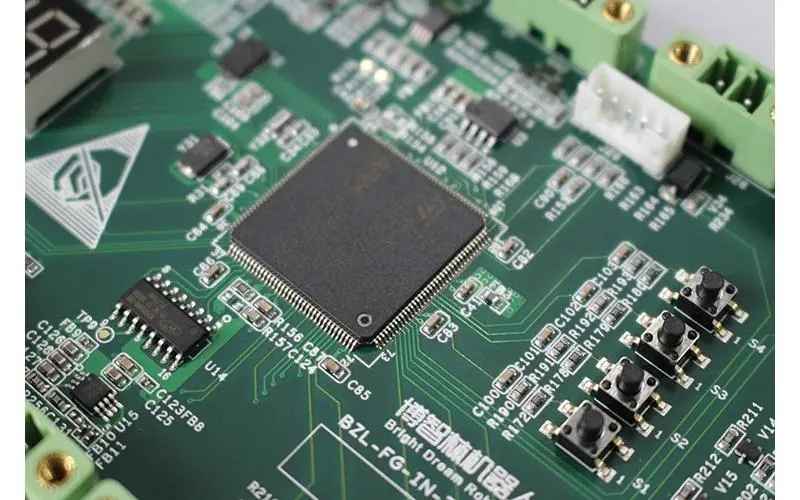

In fact, when circuit boards were first introduced, they were almost all designed with traditional insertion operations All circuit boards need wave soldering At that time, these boards were only one-sided; After the invention of SMT, the mixed use of surface mount and wave soldering began to appear. Because a large part of parts could not be converted to Surface Mount Technology at that time, that is, there were many traditional parts, so all parts must be put into the design of circuit boards The inserts are arranged on the same side and the other side is used for wave soldering The wave soldering side of this SMT part must be fixed with red glue to prevent the part from falling into the welding furnace when passing through the wave soldering furnace Now almost all the boards of directors have adopted the surface mount process on both sides, but it seems that there are still very few parts that cannot use the surface mount process. In this regard, this selective wave soldering process CAMe into being

The above is the explanation given by the editor of PCB circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱