Relationship between PCB and integrated circuit and PCB dry film pasting

PCB manufacturing, PCB design and PCBA processing manufacturers explain the relationship between PCB and integrated circuit and PCB dry film

In the process of learning electronICs, we often see printed circuit boards (PCB) and integrated circuits (ICs). Many people are "stupid and indistinct" about these two concepts. In fact, they are not so complicated. Today, let's clarify the difference between PCB and integrated circuit.

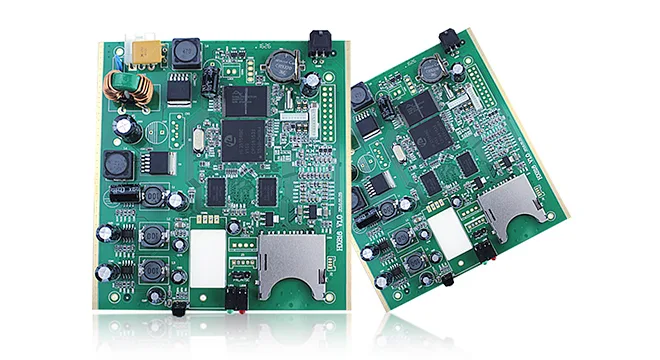

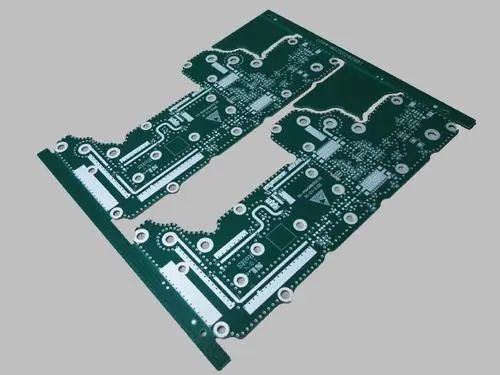

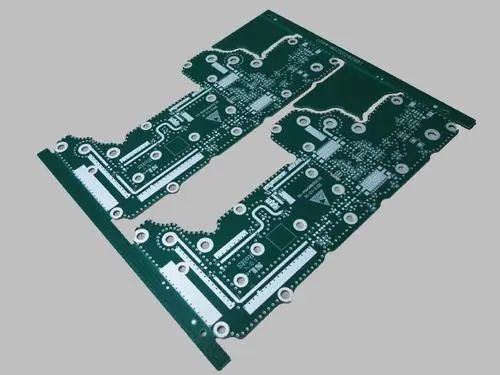

What is a PCB?

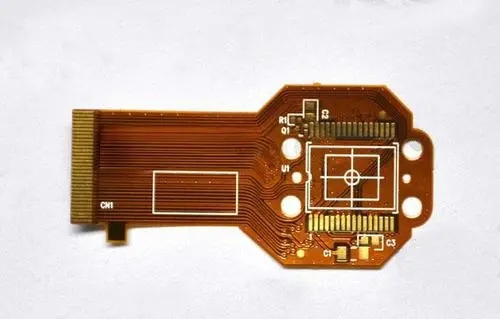

PCB (printed circuit board), also known as printed circuit board in Chinese, is an important electronic component, a support for electronIC components, and a carrier for electrical connection of electronic components. Because it is made by electronic printing, it is calLED "printed" circuit board.

Current circuit boards are mainly composed of pattern, dielectric layer, through hole/via, solder resistant/solder mask, Legend/MARKing/Silk screen, surface finish, etc.

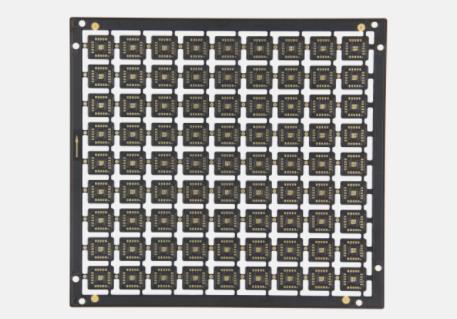

Advantages of PCB: high-density, high reliability, designability, producibility, testability, assemblability, maintainability.

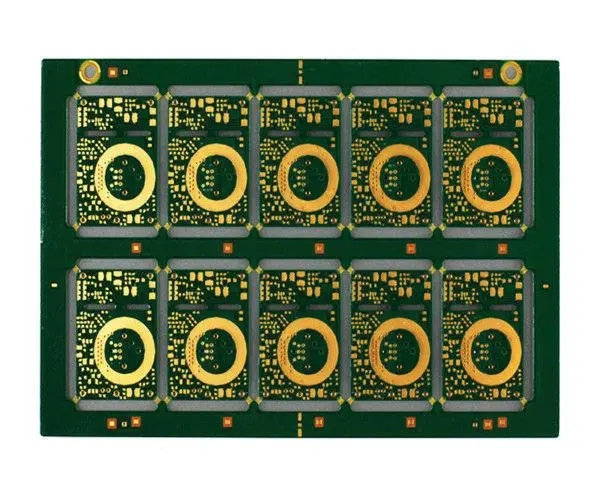

What is an integrated circuit?

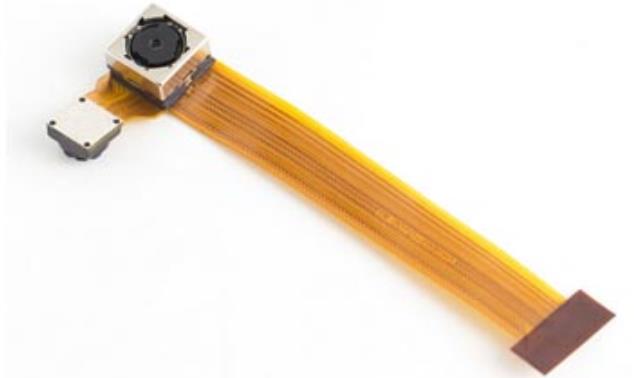

Integrated circuit is a kind of micro electronic device or component. Using a certain process, the transistors, resistors, capacitors, inductors and other components required in a circuit and their wiring are interconnected together, made on a SMAll piece or several small pieces of semiconductor chips or dielectric substrates, and then packaged in a tube shell to become a micro structure with the required circuit functions; All the components have formed a whole in structure, which makes the electronic components move towards miniaturization, low power consumption, intelligence and high reliability. It is represented by the letter "IC" in the circuit.

According to their different functions and structures, integrated circuits can be divided into analog integrated circuits, digital integrated circuits and mixed digital/analog integrated circuits.

Integrated circuit has the advantages of small size, light weight, few outgoing lines and welding points, long service life, high reliability, good performance, low cost and convenient for large-scale production.

Relationship between PCB and IC

Integrated circuit generally refers to the integration of chips. For example, the Beiqiao chip on the motherboard and the CPU are all called integrated circuits, and the original name is also called integrated block. PCB refers to the circuit board we usually see, as well as printed and soldered chips on the circuit board.

Understanding of the relationship between the two: integrated circuit (IC) is welded on PCB; PCB board is the carrier of integrated circuit (IC).

To put it SIMply, integrated circuit is to integrate a general circuit onto a chip, which is a whole. Once it is damaged internally, the chip will be damaged, while PCB can weld components by itself, and components can be replaced if they are damaged.

Summary of common problems and solutions of PCB dry film pasting

With the continuous development of the electronic industry and the continuous upgrading of products, in order to save board space, the lines of many boards are already very small when they are designed. The previous wet film can no longer meet the current graphic transfer process. Now, generally, small lines are produced with dry film. What problems do we have in the film coating process? The following sections will introduce them.

Summary of common problems and solutions of PCB dry film pasting

01 - Bubbles appear between the dry film and the copper foil surface

Bad problem: selecting flat copper foil is the key to ensure no bubbles.

Solution: Increase the pressure of PCB pasting film, and handle the plate with care.

Bad problems: the surface of the hot pressing roller is uneven, with pits and drilling dirt on the adhesive film.

Solution: Regularly check and protect the flatness of the hot pressing roll surface.

Bad problem: The temperature of PCB film is too high, resulting in wrinkling of some contact materials due to temperature difference.

Solution: Reduce the temperature of PCB film.

02 - The dry film is not firmly stuck on the copper foil

Unfavorable problem: the copper foil surface is not cleaned properly, and direct operation will leave oil stain or oxide layer.

Solution: Wear gloves to wash the board.

Adverse problems: The quality of dry film solvent is not up to standard or has expired.

Solution: The manufacturer should select high-quality dry film and regularly check the shelf life of dry film.

Bad problems: fast transmission speed, low PCB film temperature.

Solution: Change the speed and temperature of PCB pasting.

Bad problem: The processing environment humidity is too high, which leads to the extension of the dry film bonding time.

Solution: Keep the relative humidity of the production environment at 50%.

03 - Dry film wrinkling

Bad problem: The dry film is too sticky, so place the board carefully during operation.

Solution: In case of contact, handle it in time.

Bad problem: The board is overheated before the PCB film is applied.

Solution: The preheating temperature of the board should not be too high.

04 - Residual glue

Bad problem: poor dry film quality.

Solution: Replace the dry film.

Bad problem: exposure time is too long.

Solution: Have an understanding of the materials used and conduct reasonable exposure time.

Bad problem: Developer failure.

Solution: Change the developer.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the relationship between PCB and integrated circuit and PCB dry film.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱