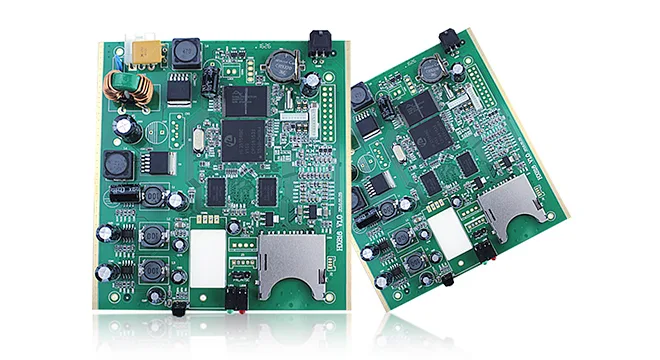

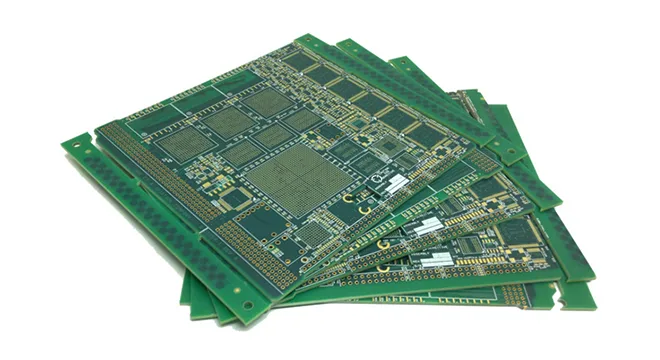

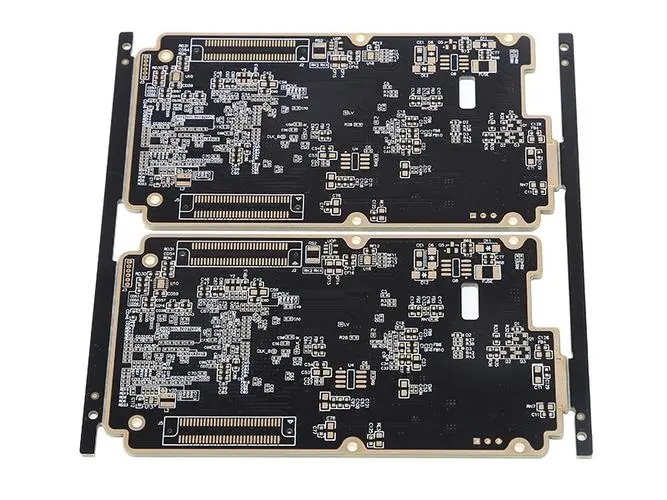

Introduction to PCB manufacturing and packaging process

PCB manufacturing, PCB design, PCBA processing manufacturer will explain PCB manufacturing and packaging process

Process destination

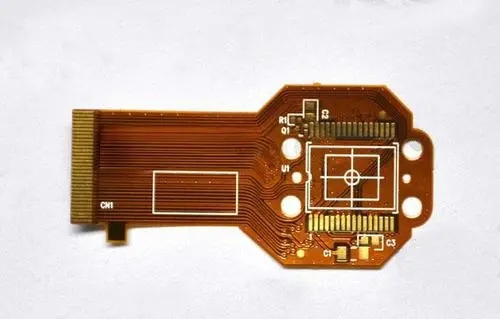

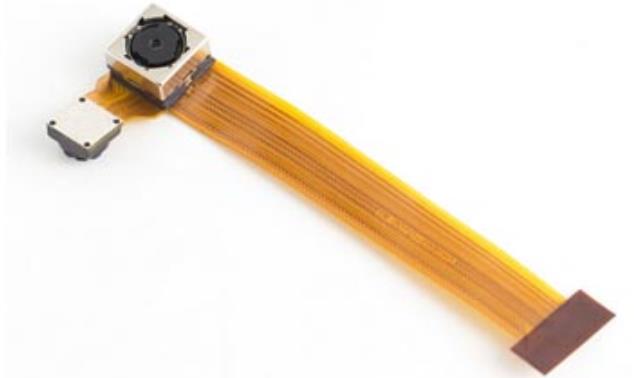

This step of "packaging" is generally less important in PCB plants than all STEPs in the manufacturing process. The main reason is, on the one hand, of course, that it does not generate additional value, and on the other hand, that Taiwan's manufacturing industry has long ignored the immeasurable benefits that product packaging can bring. Japan has done the best in this regard. Careful observation of some Japanese household electronICs, daily necessities, even food, etc., with the same functions, will make people prefer to spend more money to buy Japanese goods. This has nothing to do with worshiping foreign countries and flattering Japan, but is a grasp of consumer mentality. Therefore, packaging will be discussed independently to let PCB industry know that SMAll improvements may have great effects. For another example, Flexible PCB is usually a small piece with a large number. The packaging method of Japan Company may be specially molded for the shape of a product to be used as a packaging container, which is convenient to use and can be used for protection.

2. Discussion on early packaging

For the early packaging methods, see the outdated shipping packaging methods in the table, and list their missing details. At present, some small factories still use these methods for packaging.

The capacity of domestic PCB is expanding rapidly, and most of it is for export. Therefore, the competition is very fierce, not only among domestic manufacturers, but also with the top two PCB manufacturers in the United States and Japan. In addition to the technical level and quality of the products being recognized by customers, the quality of packaging needs to be satisfied with customers. Almost a small scale electronic factory will now require PCB manufacturers to provide packaging for shipment. The following items must be noted, and some even directly provide packaging specifications for shipment.

1. Must be vacuum packed

2. The number of plates per stack is limited according to the size

3. The specification of the coating density of each layer of PE adhesive film and the provisions of the width of the reserved edge

4. Specification requirements for PE adhesive film and air bubble sheet

5. Carton weight specification and others

6. Is there any special regulation to slow down the flushing before placing the board inside the carton

7. Tolerance specification after sealing

8. Weight limit of each case

At present, vacuum skin packaging in China is almost the same, with the main differences being the effective working area and the degree of automation.

2. Vacuum Skin Packaging

2.1 Operating procedures

A. Preparation: locate the PE film, manually operate each mechanical action to check whether it is normal, set the PE film heating temperature, vacuum suction time, etc.

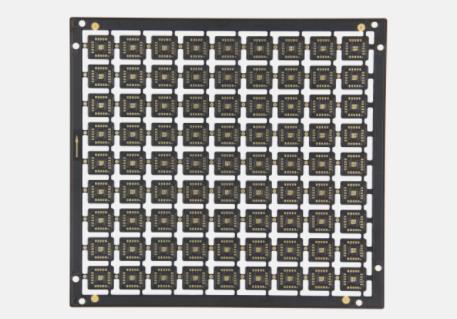

B. Stacking boards: When the number of stacked boards is fixed, their height is also fixed. At this time, it is necessary to consider how to stack them to maximize the output and save materials. The following are the principles:

a. According to the specification (thickness), (standard is 0.2m/m) of PE film, the distance between each stack of boards is based on the principle of heating, softening and lengthening. At the same time of vacuuming, the coated boards are stuck to the bubble cloth. The spacing shall be at least twice of the total plate thickness of each stack. Too much wastes materials; If it is too small, it is difficult to cut and it is very easy to fall off or cannot be stuck at all.

b. The distance between the outermost plate and the edge must also be at least one time of the plate thickness.

c. If the size of PANEL is not large, materials and manpower will be wasted according to the above packaging methods. If the quantity is large, it can also be used as a container in the same way as soft board packaging, and then used as a PE film shrink packaging. There is another way, but the consent of the customer must be obtained. There is no gap between each stack of boards, but they are separated by cardboard, and the appropriate number of stacks is taken. There is also cardboard or corrugated paper underneath.

C. Start: A. Press Start, the heated PE film is LED by the pressing frame to descend and cover the worktop B. Then the vacuum pump at the bottom is used to absorb air and cling to the circuit board and adhere to the bubble cloth. C. Lift the outer frame after the heater is removed to cool it down D. Cut off the PE film and pull the chassis to separate each stack

D. Packing: the packing method, if specified by the customer, must be in accordance with the customer's packing specification; If not specified by the customer, the packing specification in the factory must also be established based on the principle of protecting the board transportation process from external force damage. Precautions, especially the packing of exported products mentioned earlier, must be paid special attention.

E. Other precautions:

A. Information that must be written outside the box, such as "mouthpiece", material number (P/N), version, cycle, quantity, importance, etc. And Made in Taiwan (if exit).

b. Relevant quality certificates, such as slices, weldability reports, test records, and various test reports required by customers shall be attached and placed in the manner specified by customers. Packaging is not a big subject. Doing it carefully can save a lot of trouble that should not happen.

PCB manufacturing, PCB design and PCBA processing manufacturers will explain the PCB manufacturing and packaging process.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱