It is the key to return PCB copy board of intelligent bICycle to users

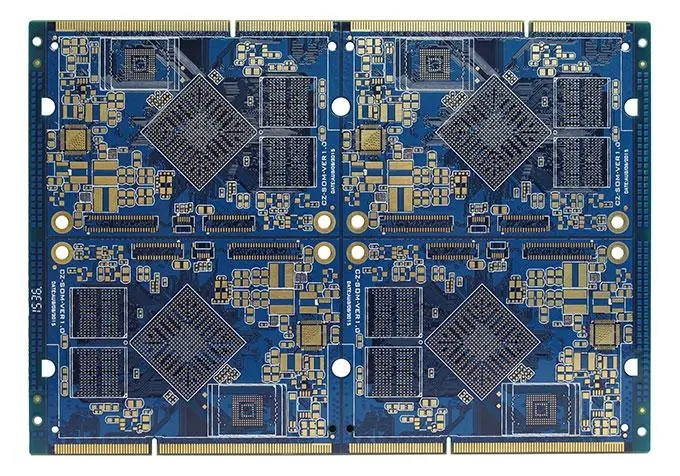

PCB manufacturing, PCB design and PCBA processing manufacturers explain that it is the key to return SMArt bicycle PCB copy to users

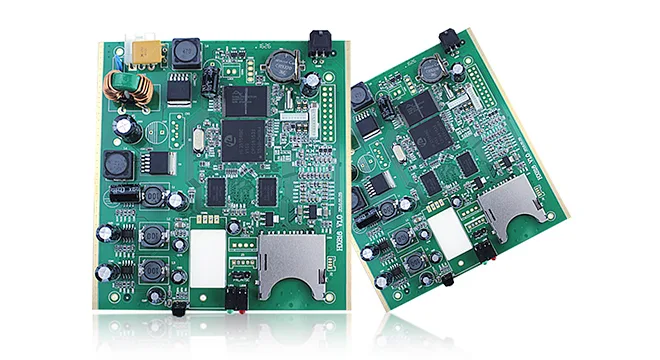

In the era of intelligent hardware, Inventive Lenovo is the main driver of the rebirth of intelligent devices. Although smart phones and smart TVS were once relatively common, smart bicycles are still in the prototype of "bird eggs". Although the online news about smart bikes is all over the country, and many giant enterprises are also very optimistic about the MARKet opportunities of smart bikes, can PCB copy boards at the bottom play well without real smart bikes or circuit boards?

There is still one kilometer left for PCB copy

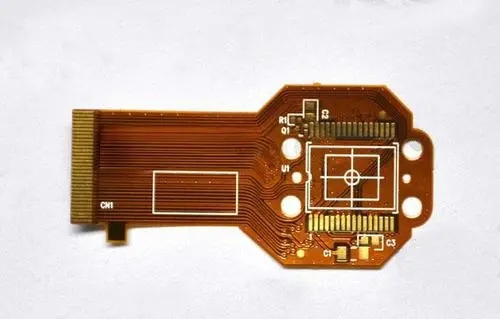

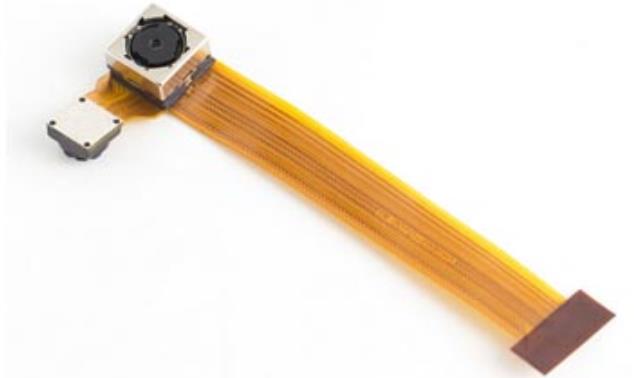

Although PCB copying enterprises are also very hungry for the huge domestic market of intelligent bicycles, they do not have such a strong team of experts and capital as brand enterprises, and it is difficult to achieve innovation. Don't worry. There is still one kilometer left for PCB copying enterprises. Most intelligent bicycle products have intelligent functions such as anti-theft alarm, navigation, data monitoring, and sharing social platforms with mobile Internet. PCB copying can also play a great role in the R&D process of intelligent bicycles by doing more reverse research and secondary innovation and development in this area.

The key is to return PCB copy to users

At present, China has the largest number of bicycles in the world, and the degree of bicycle sports is the last in the world. But from another perspective, this shows that the bicycle industry has a lot of potential, and I believe that smart bicycles will be a bright spot in the intelligent world in the future. Through the digestion and absorption of relevant anti-theft alarm equipment, navigation equipment, data monitoring equipment and other PCB copying devices, we can provide customers with better service and experience, shorten the project research and development cycle for enterprises focusing on intelligent bicycle research and development, and provide users with products with lower cost, durable, anti-theft, waterproof and other functions. The ultimate regression of PCB copying is the applicability felt by users.

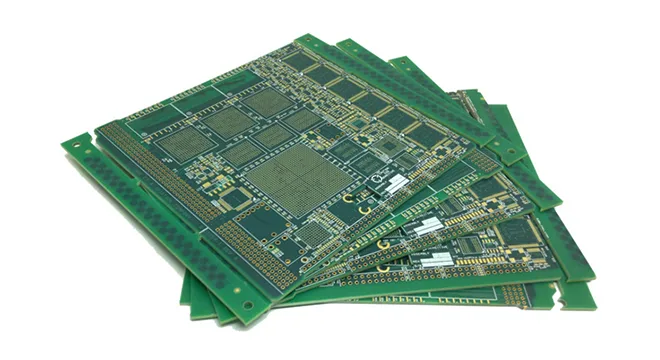

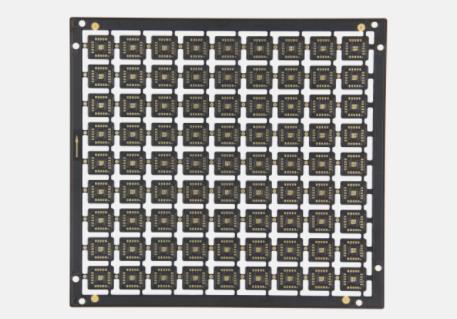

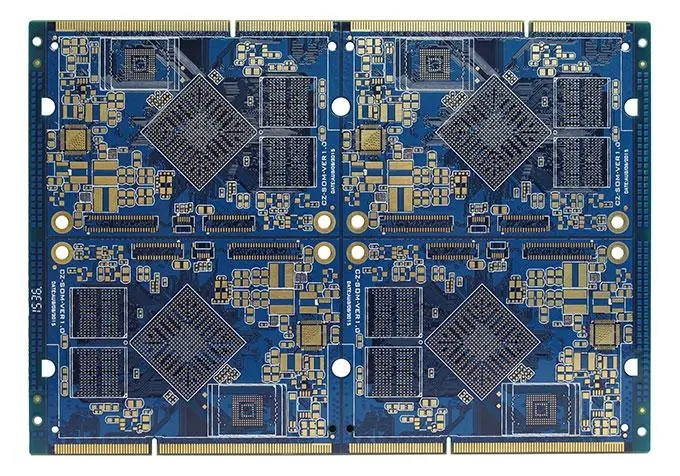

As far as many experts in the industry are concerned, the most prominent problem of domestic robots at present is that the central technology and key parts are under the control of others. Although China is already the largest robot market in the world, domestic robots are still at the stage of assembly and imitation, and there is no talent for innovation. The robot "Made in China" has a long way to go, and its shortcomings mainly lie in the lack of application system development and the lack of central parts. In order to break through these bottlenecks, China has always chosen the way of PCB copy reverse innovation to break through in the early days when high-tech products overtook at corners.

Secondary development of PCB board for robot application system

Because our country has little experience in the design of robot application system. Although it is possible to buy foreign robots, most robots are not available after purchase, but require secondary development. For example, a welding robot can only work if the factory needs to develop a set of welding application system. Although many robot consumer enterprises in China have the ability to consume complete machines, they cannot stop the complex late system development. The application system not only represents the technical strength, but also has high profits. Therefore, it is urgent to break the application system development, and the first thing to do is to improve my design experience in this area. PCB copying can help us quickly learn, digest and absorb foreign advanced robot system development experience.

The key points of PCB copying for robot parts are broken

According to incomplete statistics, 80%~90% of domestic robots use foreign reducers, 60%~70% use foreign motors, and 40%~50% use foreign controllers. China's robot industry chain has not been formed yet. Even for companies like Xinsong, its reducer, motor, bearing and other central parts of robots are all from abroad. This means that all our domestic robots can do is shell, and all the central parts are foreign. This increases the cost and makes the domestic robot in an advantage in the competition. To solve this problem, we must use our strength! PCB manufacturers, PCB designers and PCBA manufacturers explain that it is the key to return the PCB copy of smart bicycles to users.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱