Circuit board factory: what are the colors of high-frequency circuit boards

PCB manufacturers, PCB designers and PCBA manufacturers explain to you what PCB manufacturers pay attention to: the color of high-frequency PCB

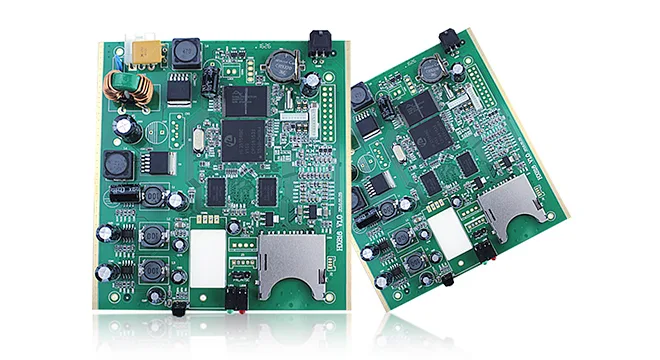

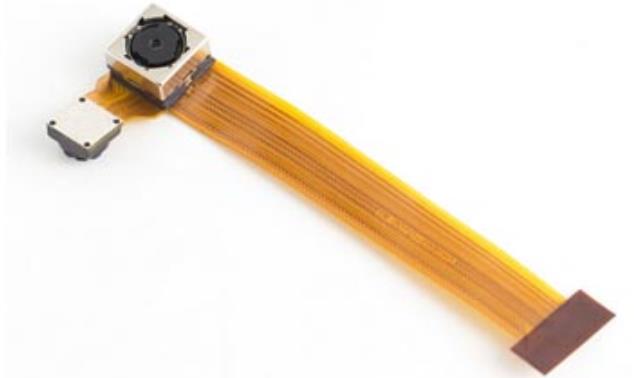

High Frequency Circuit Board is a special circuit board with high electromagnetIC frequency. Generally speaking, high frequency can be defined as the frequency above 1GHz. Its physical performance, accuracy and technical parameters are very high, and are commonly used in automotive anti-collision systems, satellite systems, radio systems and other fields.

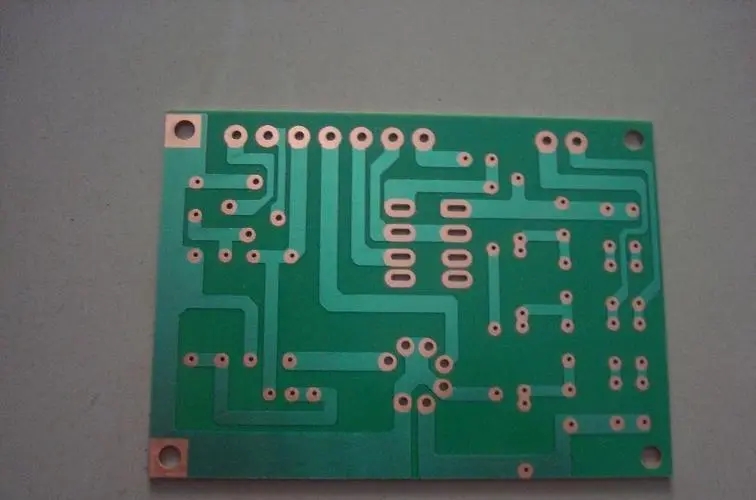

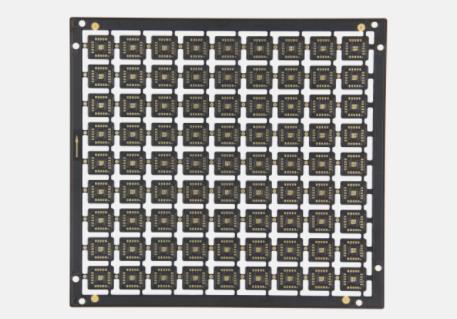

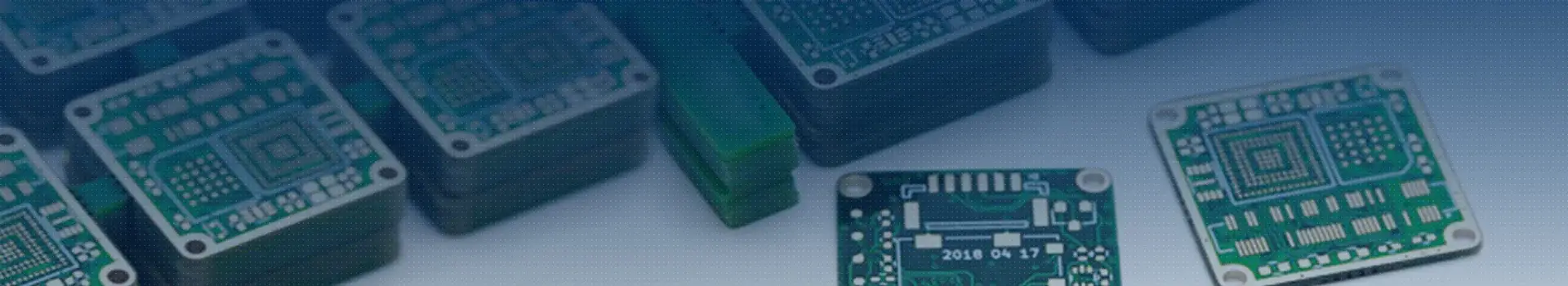

What is the color of the high-frequency circuit board? As the name implies, when you get a high-frequency circuit board, you can see the color of the high-frequency circuit board oil most intuitively. This is what we generally refer to as the color of the high-frequency circuit board. The common colors are green, blue, red and black.

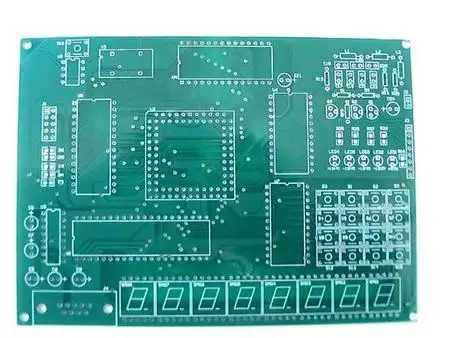

Green ink is by far the most widely used, the longest history, and the cheapest in the current MARKet, so green is used by a large number of manufacturers as the main color of their products.

2. Common high-frequency circuit boards are red, yellow, green, blue and black. However, due to the manufacturing process and other problems, the quality inspection process of many lines must still rely on the visual observation and identification of workers (of course, most of the current use of flying needle testing technology). It is a very tiring work process to keep your eyes on the boards under strong light. Green does not hurt your eyes, so most manufacturers on the market use green high-frequency circuit boards.

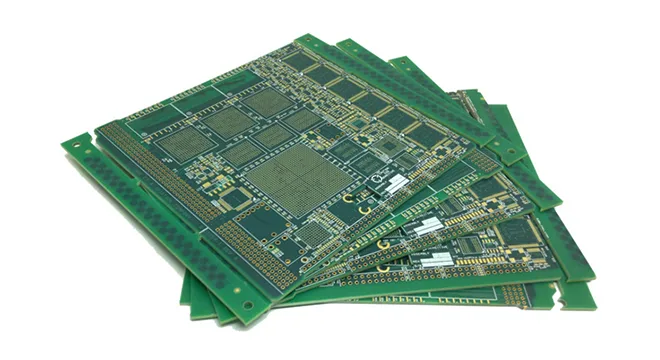

When SMT is welding components, high-frequency circuit boards need to go through processes such as solder paste and patch, and the final AOI verification. These processes require optical positioning calibration. The green background is better for instrument recognition.

3. Generally, the whole high-frequency circuit board product needs to go through the process of board making and SMT in the manufacturing process. When making boards, there are several processes that must go through the yellow light room, because the effect of green in the yellow light room is better than other colors, but this is not the main reason.

4. The principle of blue and black is that they are doped with cobalt, carbon and other elements respectively, which has a certain conductivity. Short circuit is likely to occur when the power is on. In addition, green high-frequency circuit boards are relatively environmentally friendly, and generally do not release toxic gases when used in a high-temperature environment.

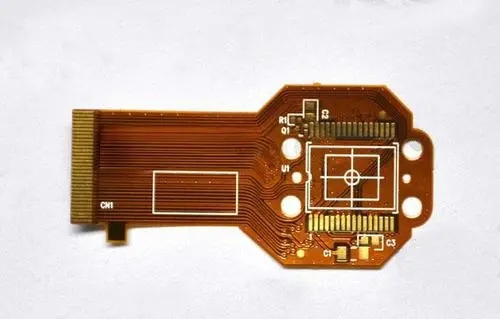

On the other hand, a SMAll number of high-frequency board manufacturers in the market will use black high-frequency circuit boards. The main reasons for this are as follows:

① It looks high-end;

② It is not easy to see the wiring in the black high-frequency circuit board, which brings some difficulties to board reading;

What Xiao Bian learned is that most of the embedded Android boards are black high-frequency circuit boards.

5. Since the middle and late last century, the industry has begun to pay attention to the color of high-frequency circuit boards. This is mainly because many high-end board types of first-line large factories have adopted the green color design of high-frequency circuit boards. Therefore, people gradually believe that if the color of high-frequency circuit boards is green, they must be high-end.

In fact, based on various reasons, Xiaobian believes that it is better to use green high-frequency circuit boards in general. circuit board manufacturers, circuit board designers and PCBA processors will explain to you what the Circuit board manufacturers pay attention to: the color of high-frequency circuit boards.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱