How to specify impedance control requirements for high-frequency board manufacturers

circuit board manufacturers, circuit board designers and PCBA manufacturers explain how high-frequency board manufacturers specify impedance control requirements

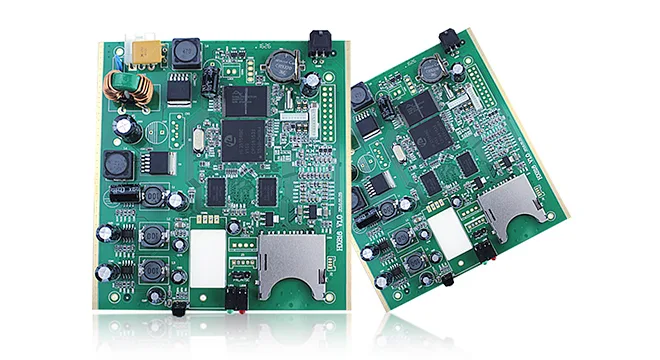

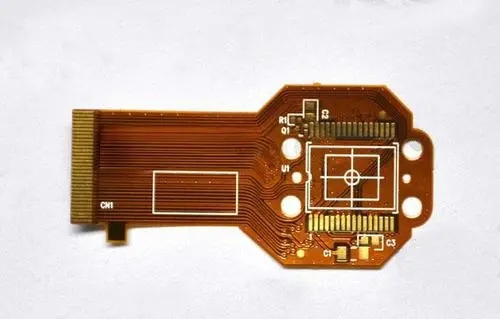

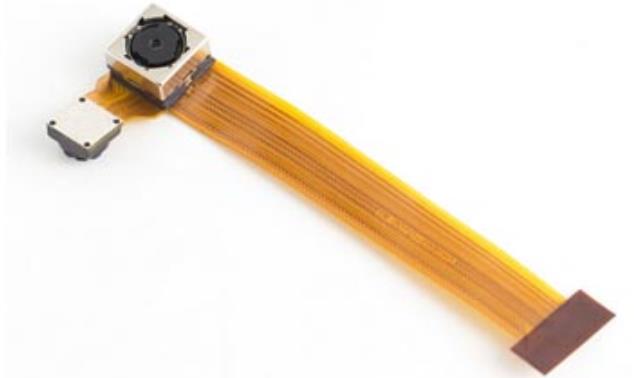

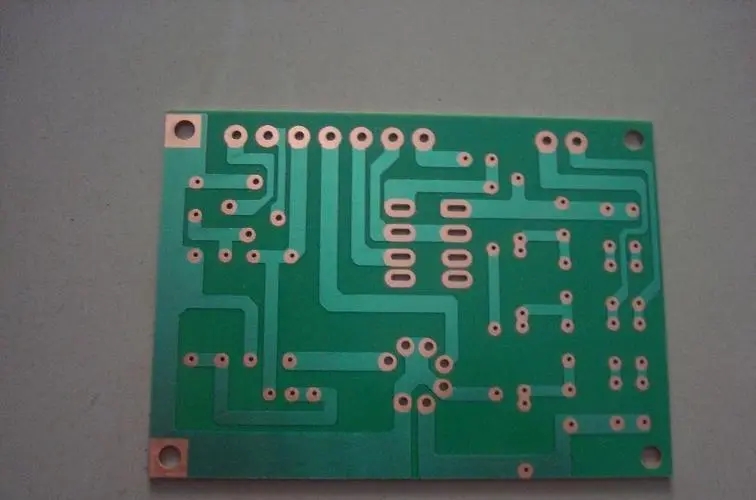

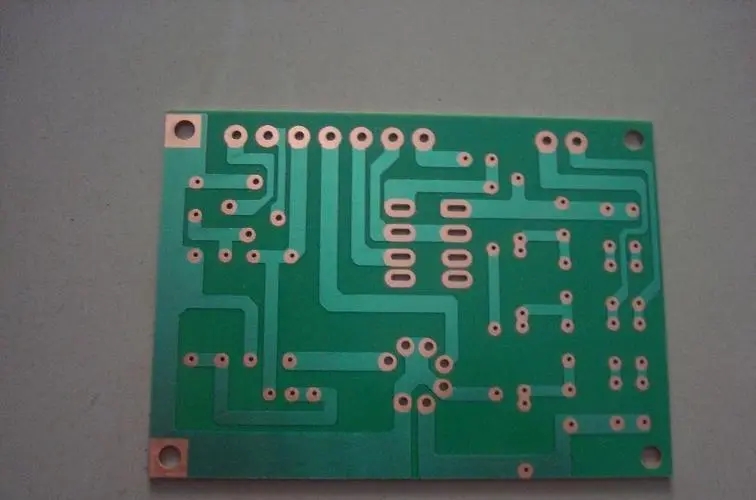

High Frequency Circuit Board is a special circuit board with high electromagnetIC frequency. Generally speaking, high frequency can be defined as the frequency above 1GHz. Its physical performance, accuracy and technical parameters are very high, and are commonly used in automotive anti-collision systems, satellite systems, radio systems and other fields.

As an outsider, you may not know the three letters of PCB, but if you say its full name is printed circuit board, you will be enlightened. PCB is an important electronic component, a commodity in our daily life, and is inseparable from our daily life. What are the unique advantages of PCB high-frequency board? We asked several companies of Shenzhen HF board and made the following analysis:

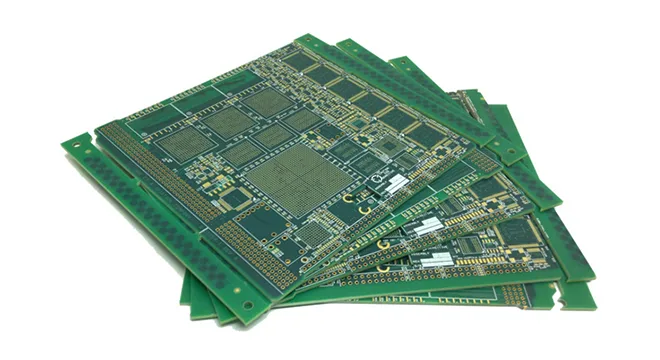

1. High density and high reliability

For deCADes, the high density of printed circuit board/PCB high-frequency board has been developing with the improvement of integrated circuit integration and installation technology. Through a series of inspections, tests and aging tests, the processing of Shenzhen high-frequency boards can be guaranteed to work reliably for a long time (service life, usually decades).

2. Testability and assembly

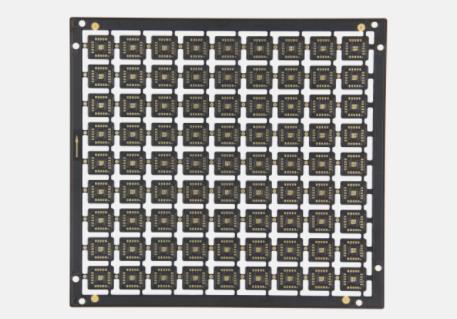

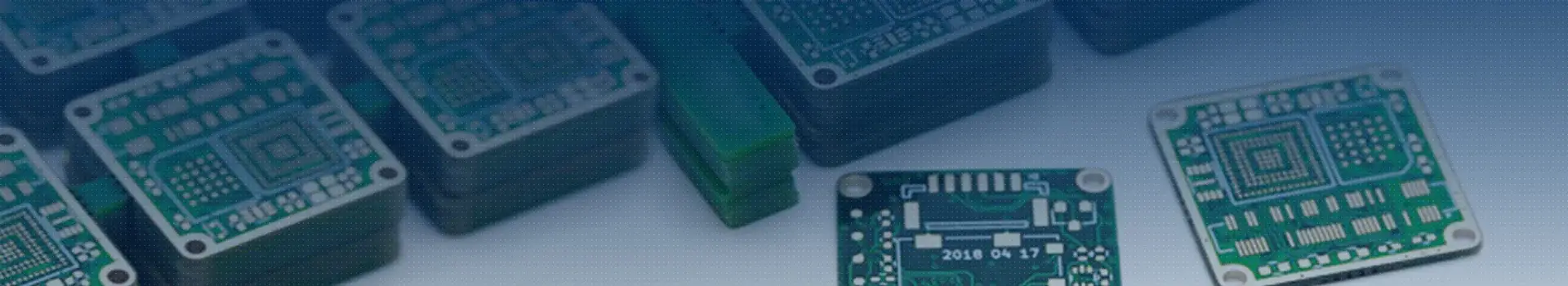

Shenzhen high-frequency board manufacturers have established relatively complete test methods, test standards, various test equipment and instruments to test and identify the product qualification and service life of Shenzhen high-frequency board manufacturers. PCB high-frequency board products are not only convenient for standardized assembly of various components, but also can be automated and large-scale batch production, so Shenzhen high-frequency board with reliable quality has outstanding advantages. The testability and assemblability of high-frequency board promote the development of this industry, and also accelerate the continuous expansion of this industry in China.

3. Designability and producibility

For various performance requirements (electrical, physical, chEMIcal, mechanical, etc.) of high-frequency board manufacturers, the printed high-frequency Board Design can be realized through standardization, normalization, etc., with short time and high efficiency. With modern management, standardized, scaLED and automated production can be carried out to ensure product quality consistency.

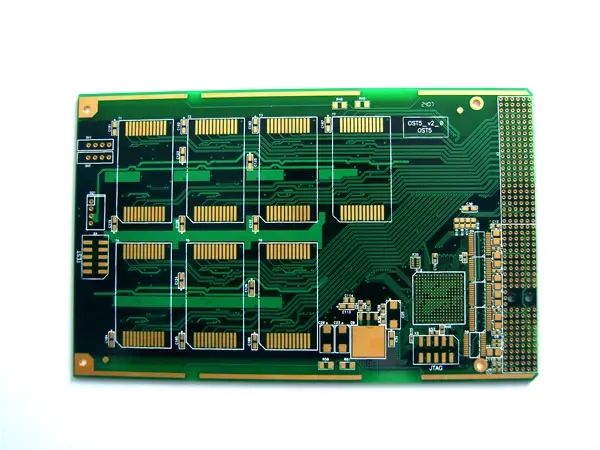

4. Strong maintainability

As high-frequency board products and various component assembly parts are designed and produced in a standardized way, various components used on high-frequency boards are also standardized. Therefore, once the system fails, it can be replaced and the system can be recovered quickly, which means stable performance.

The PCB high-frequency board industry started relatively late in our country, so the current technical level has reached the world's advanced level. However, this is not the focus of development for many manufacturers of Shenzhen high-frequency boards in China. Many companies in China have mastered the world's advanced technology of Shenzhen high-frequency boards, and if the technology of China's PCB high-frequency board industry will be ahead of the world's advanced level in time.

The circuit board manufacturer, circuit board designer and PCBA processor will explain how the high-frequency board manufacturer specifies impedance control requirements.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱