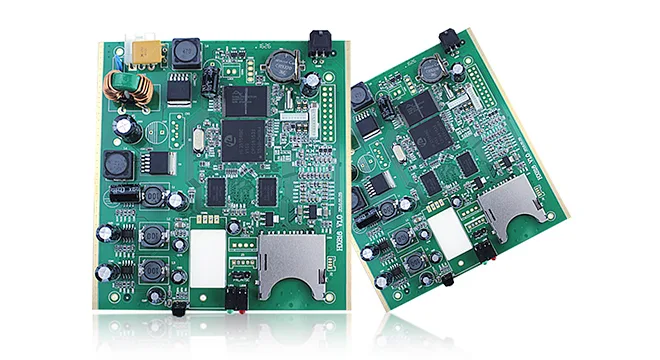

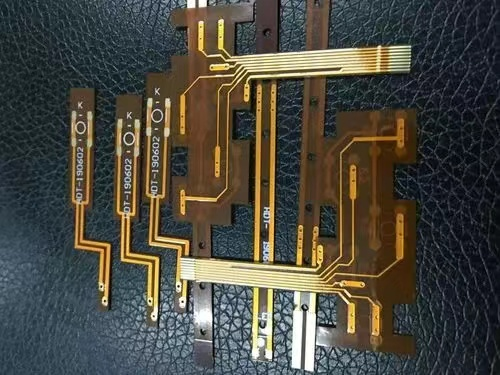

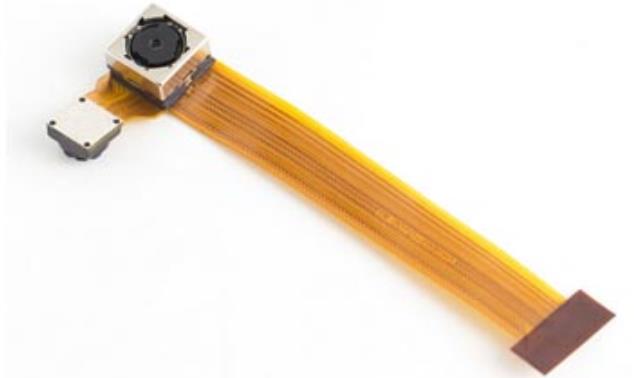

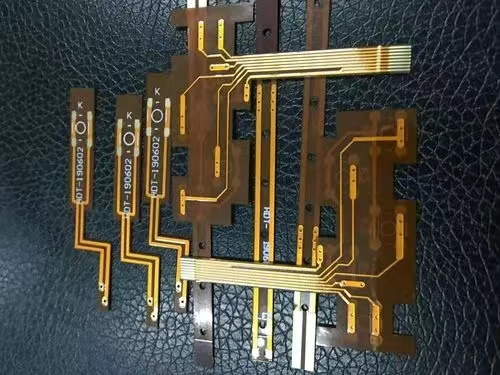

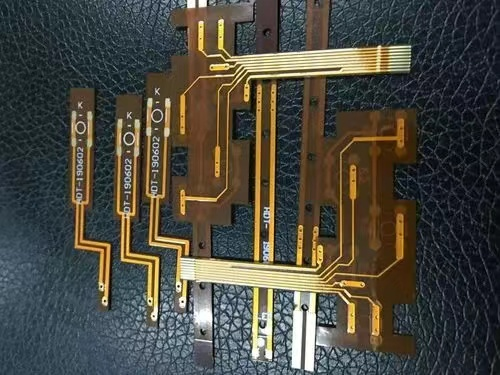

With the rapidly growing field of electronICs and telecommunications engineering demanding technological innovation, engineers and scientists are constantly looking for novel ways to improve the quality, life cycle and reliability of end products. To this end, flexible PCB materials are the focus of today's research. Flexible PCBs can be found in almost all Electronic devices around us such as printers, scanners, HD CAMeras, mobile phones, calculators, etc. Therefore, the research on flexible PCB materials and the improvement of the manufacturing process can minimize the production cost and improve the quality and reliability. Final product. In this article, we will analyze the main types of materials used in the flexible PCB manufacturing process.

Properties of flexible PCB:

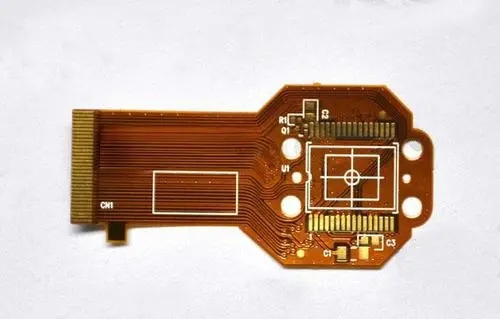

We know that flexible PCBs can be easily bent and can mount tiny electronIC components. It's also very lightweight and ultra-thin, so it can fit in any cubicle or enclosure designed for themed electronics or final product. flexible printed circuit boards are best suited for applications that need to address housing space constraints.

Common substrate material types for flexible PCBs:

Matrix:

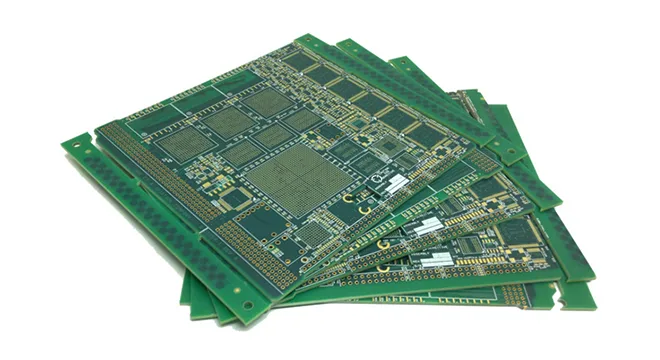

The most important material in a flexible PCB or rigid PCB is its base substrate material. It is the material on which the entire PCB stands. In rigid PCBs, the substrate material is usually FR-4. However, in Flex PCB, the commonly used substrate materials are polyimide (PI) film and PET (polyester) film, in addition to this, polymer films such as PEN (polyethylene phthalate) can also be used Diester), PTFE and Aramid etc.

Polyimide (PI) "thermoset resins" are still the most commonly used materials for Flex PCBs. It has excellent tensile strength, is very stable over a wide operating temperature range of -200 OC to 300 OC, chEMIcal resistance, excellent electrical properties, high durability and excellent heat resistance. Unlike other thermoset resins, it retains its elasticity even after thermal polymerization. However, PI resins have the disadvantage of poor tear strength and high moisture absorption. PET (polyester) resins, on the other hand, have poor heat resistance, "making them unsuitable for direct soldering", but have good electrical and mechanical properties. Another substrate, PEN, has intermediate-level performance better than PET, but not better than PI.

Liquid Crystal Polymer (LCP) Substrates:

LCP is a rapidly popular substrate material in Flex PCBs. This is because it overcomes the shortcomings of PI substrates while maintaining all the properties of PI. LCP has 0.04% moisture and moisture resistance and a dielectric constant of 2.85 at 1 GHz. This makes it famous in high-speed digital circuits and high-frequency RF circuits. The molten form of LCP, calLED TLCP, can be injection molded and pressed into flexible PCB substrates and can be easily recycled.

Resin:

Another material is the resin that tightly bonds the copper foil and base material together. The resin can be PI resin, PET resin, modified epoxy resin and acrylic resin. The resin, copper foil (top and bottom) and substrate form a sandwich called a "laminate". This laminate, called FCCL (Flexible copper Clad Laminate), is formed by applying high temperature and pressure to the "stack" through automated pressing in a controlled environment. Among these mentioned resin types, modified epoxy resins and acrylic resins have strong adhesive properties

These adhesive resins are detrimental to the electrical and thermal performance of Flex PCBs and reduce dimensional stability. These adhesives may also contain halogens which are harmful to the environment and are restricted by European Union (EU) regulations. According to these environmental protection regulations, the use of 7 hazardous substances is restricted, including lead (Pb), mercury (Hg), CADmium (Cd), hexavalent chromium (Cr 6+), polybrominated biphenyls (PBB), polybrominated DIPhenyl ethers (PBDE), Di(2-ethylhexyl) phthalate (DEHP) and butyl benzyl phthalate (BBP).

So the solution to this problem is to use a 2-layer FCCL without adhesive. 2L FCCL has good electrical properties, high heat resistance and good dimensional stability, but its fabrication is difficult and expensive.

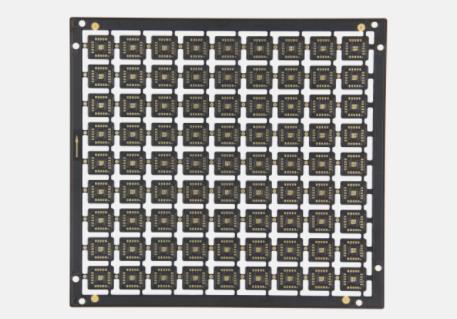

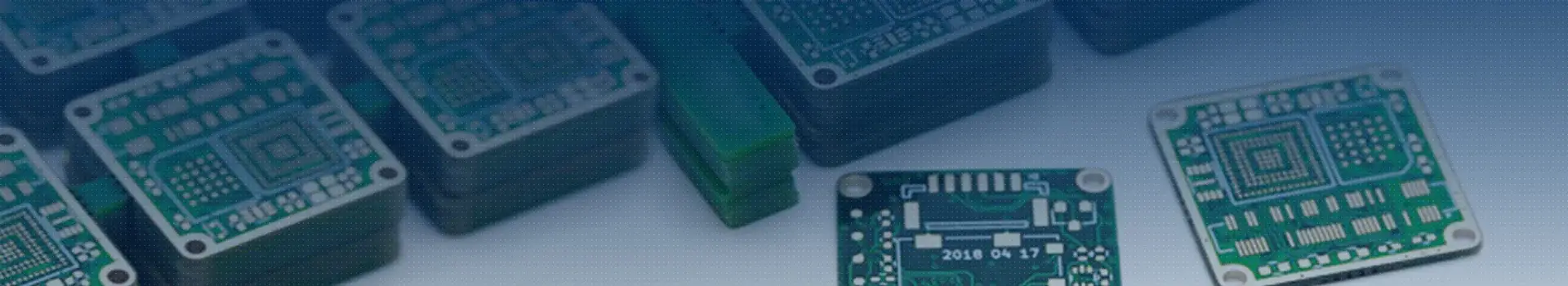

Copper foil:

Another top material in flex PCBs is copper. PCB traces, traces, pads, vias and holes are filled with copper as a conductive material. We all know the conductive properties of copper, but how to print these copper traces on a PCB is still the subject of discussion. There are two copper deposition methods on 2L-FCCL (2-layer flexible copper clad laminate) substrates. 1- Electroplating 2- Lamination. Electroplating methods have less adhesive, while laminates contain adhesives.

plating:

In cases where ultra-thin Flex PCB is required, the conventional method of laminating copper foil on PI substrate by resin adhesive is not suitable. This is because the lamination process has a 3-layer structure, i.e. (Cu-Adhesive-PI) makes the stacked layers thicker, so it is not recommended for double-sided FCCL. Therefore, another method called "sputtering" is used, in which copper is sputtered on the PI layer by wet or dry methods by "electroless" electroplating. This electroless plating deposits a very thin layer of copper (the seed layer), while another layer of copper is deposited in a next step called "electroplating", where a thicker layer of copper is deposited over a thin layer of copper (the seed layer) layer). This method creates a strong bond between PI and copper without the use of a resin adhesive.

laminated:

In this method, PI substrates are laminated with ultra-thin copper foils through a cover layer. Coverlay is a composite film in which a thermoset epoxy adhesive is coated on a polyimide film. This cover adhesive has excellent heat resistance and good electrical insulator, with flexing, flame retardant and gap filling properties. A special type of coverlay called "Photo Imageable Coverlay (PIC)" has excellent adhesion, good flex resistance and environmental friendliness. However, the disadvantage of PIC is poor heat resistance and low glass transition temperature (Tg)

Roll Annealed (RA) and Electrodeposited (ED) Copper Foils:

The main difference between the two is their manufacturing process. ED copper foil is made from CuSO4 solution by electrolytic method, in which Cu2+ is dipped into a rotating cathode roll and stripped, and then ED copper is made. While RA copper of different thicknesses is made from high purity copper (>99.98%) by pressing process.

Electrodeposited (ED) copper is more conductive than roll annealed (RA) copper, and RA is much more ductile than ED. For Flex PCB, RA is the better choice in terms of flexibility, while ED is the better choice for conductivity.

然后

聯(lián)系

電話熱線

13410863085Q Q

微信

- 郵箱